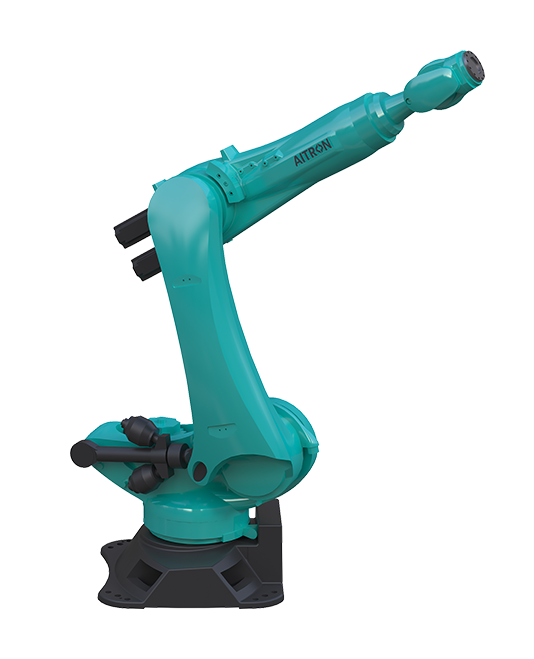

AT210R2700

Suitable for large space, large load, fast running speed, high precision requirements, such as loading and unloading, handling, palletizing, grinding and other applications.

Wrist load rating

210KGMaximum working radius

2700mmDegree of freedom of motion

6AT210R2700