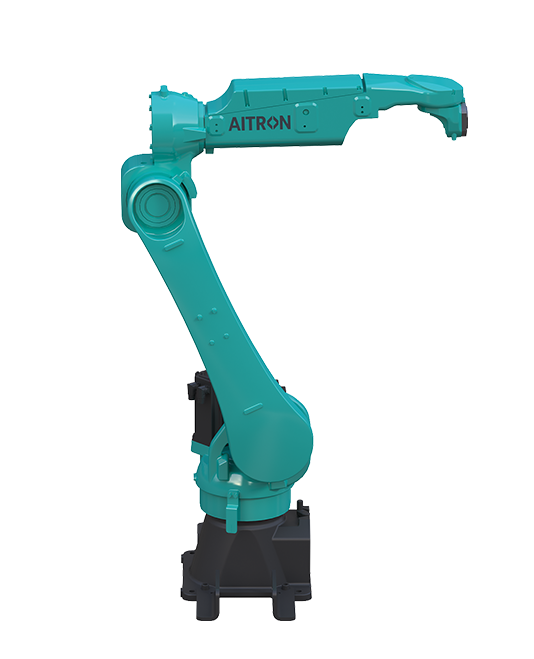

AT30R1831

Suitable for handling, code edge, assembly, loading and unloading applications.

Wrist load rating

30KGMaximum working radius

1831mmDegree of freedom of motion

6AT30R1831

Wrist load rating

30KGMaximum working radius

1831mmDegree of freedom of motion

6

| Rated load speed(°/s) | J1 | 210 |

| J2 | 210 | |

| J3 | 265 | |

| J4 | 331 | |

| J5 | 342 | |

| J6 | 572 | |

| Joint range of motion(°) | J1 | -185.5~+173.5 |

| J2 | -152.5~+94 | |

| J3 | -85.5~+217.5 | |

| J4 | ±197.5 | |

| J5 | ±177.5 | |

| J6 | ±447.5 | |

| Allowable load torque(N·m) | J4 | 62 |

| J5 | 62 | |

| J6 | 38.2 | |

| Allowable load moment of inertia(Kg·㎡) | J4 | 3.1 |

| J5 | 3.1 | |

| J6 | 1.3 | |

| IP level | body | IP54 |

| wrist | IP65 | |

| Body weight(Kg) | 320 | |

| Repeated positioning accuracy(mm) | ±0.08 | |

| Installation mode | Ground and lifting | |

| Installation environment | Ambient temperature/humidity | 0~45°C/20~85% |

| Vibration value | Less than 0.5G | |

| Other | Keep away from corrosive gases or liquids or explosive gases; Away from waterOil, dust; Keep away from electrical interference Asources. |