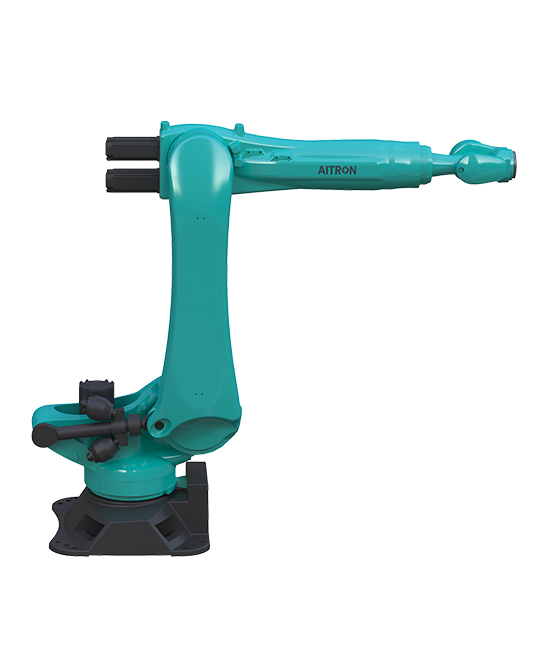

Wrist load rating

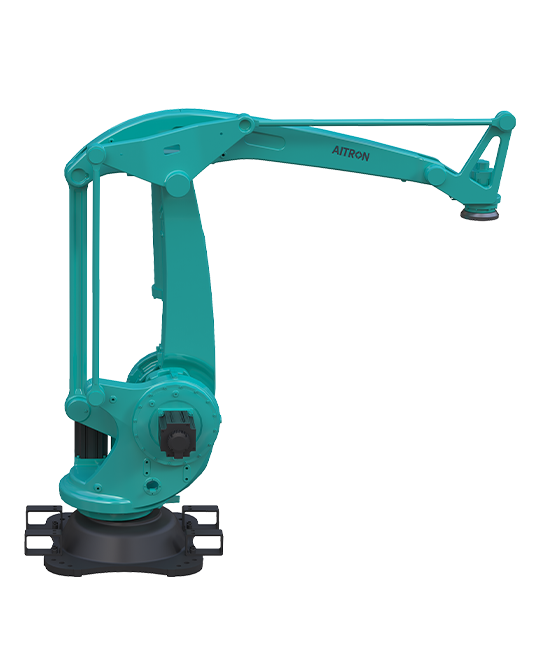

700KGKGMaximum working radius

2832mmDegree of freedom of motion

6Choose the product

Providing Power for Your Automation

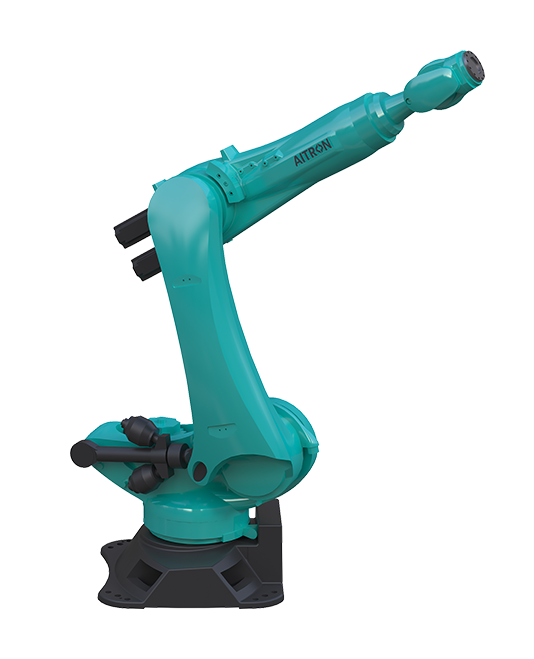

Wrist load rating

700KGKGMaximum working radius

2832mmDegree of freedom of motion

6

Wrist load rating

360KGMaximum working radius

2655mmDegree of freedom of motion

6

Wrist load rating

210KGMaximum working radius

3100mmDegree of freedom of motion

6

Wrist load rating

210KGMaximum working radius

2700mmDegree of freedom of motion

6

Wrist load rating

180KGMaximum working radius

3150mmDegree of freedom of motion

4

Wrist load rating

120KGMaximum working radius

2400mmDegree of freedom of motion

4

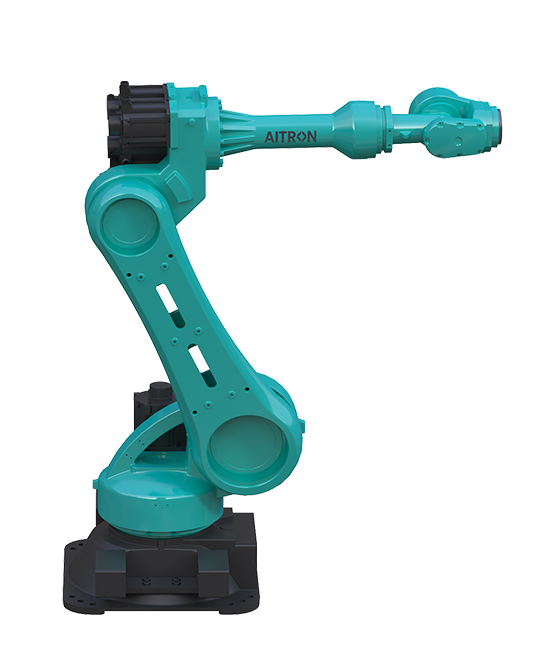

Wrist load rating

120KGMaximum working radius

2230mmDegree of freedom of motion

6

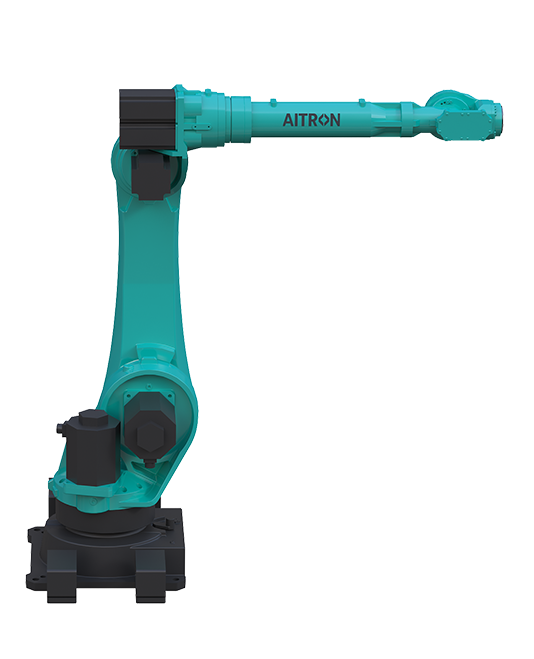

Wrist load rating

80KGMaximum working radius

2050mmDegree of freedom of motion

6

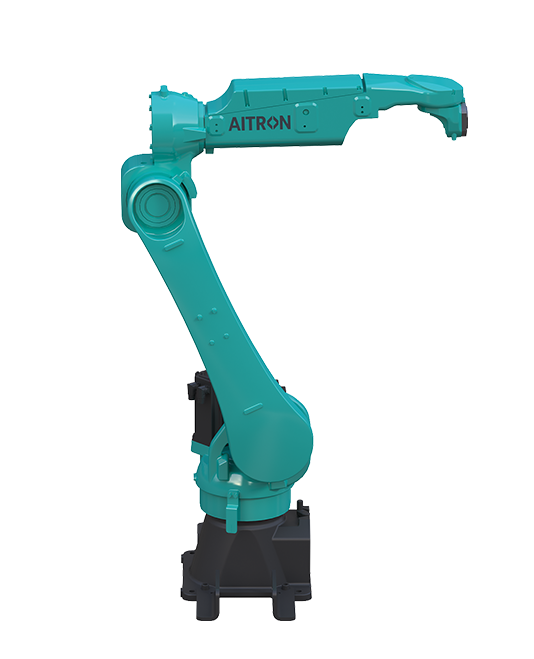

Wrist load rating

30KGMaximum working radius

1831mmDegree of freedom of motion

6

Wrist load rating

12KGMaximum working radius

1450mmDegree of freedom of motion

6

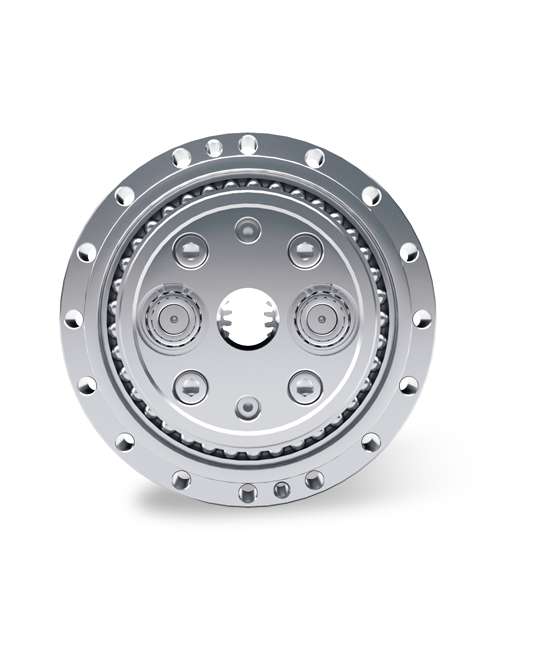

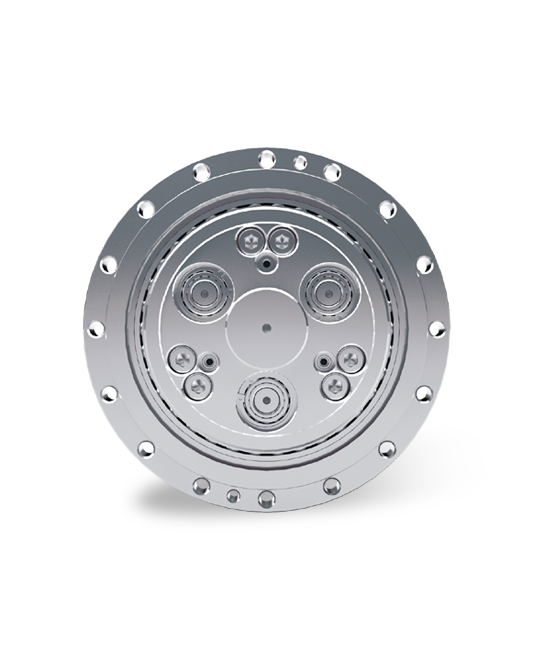

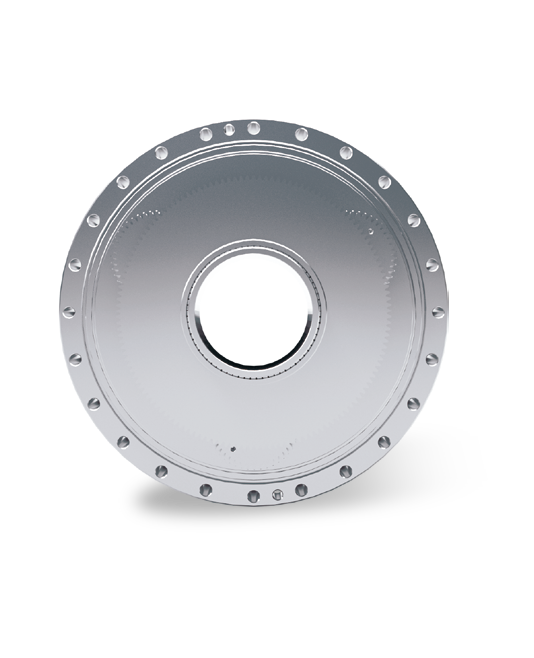

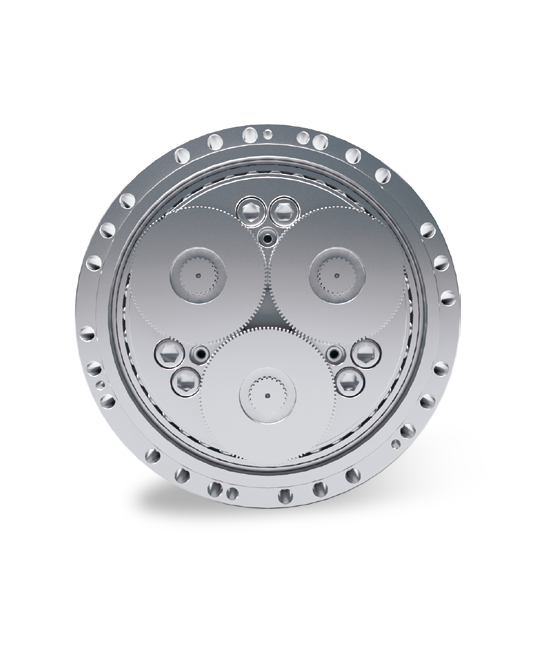

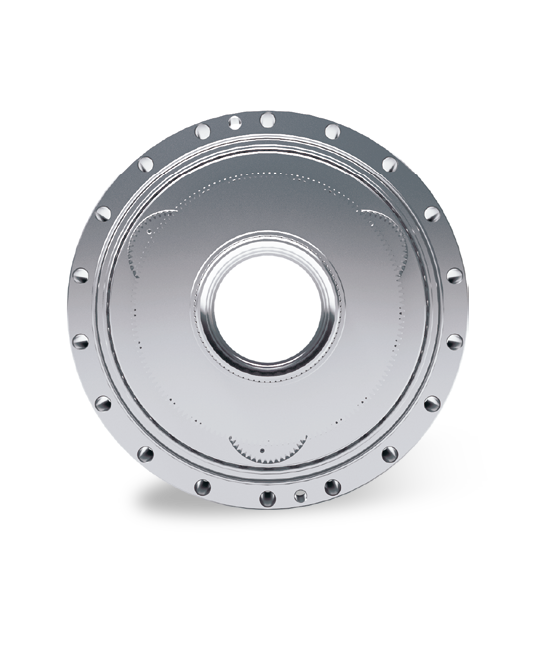

Standard Reduction Ratio

412Rated Torque

105Nm

Standard Reduction Ratio

105Rated Torque

167Nm

Standard Reduction Ratio

105Rated Torque

167Nm

Standard Reduction Ratio

105Rated Torque

412Nm

Standard Reduction Ratio

36.75Rated Torque

686Nm

Standard Reduction Ratio

121Rated Torque

784Nm

Standard Reduction Ratio

34.86Rated Torque

1960Nm

Standard Reduction Ratio

37.52Rated Torque

3136Nm

Standard Reduction Ratio

35.61Rated Torque

3136Nm

Standard Reduction Ratio

241Rated Torque

3136Nm

Standard Reduction Ratio

171Rated Torque

3136Nm

Standard Reduction Ratio

33.14Rated Torque

3920Nm

Radius of rotation

1054mmWheelbase

835mmMaximum load

1000

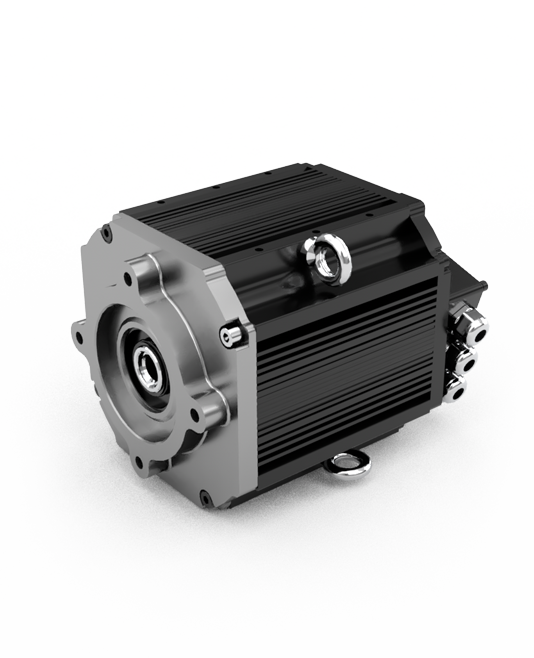

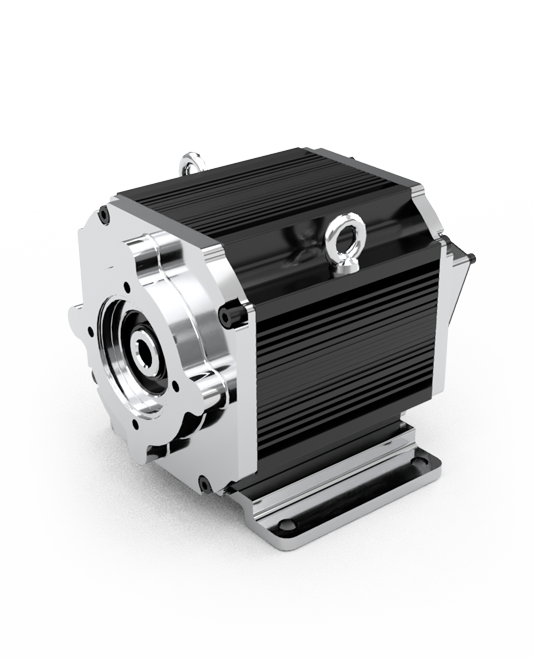

Rated Power(kW)

4-150Rated Torque(N·m)

20-800Rated Speed(rpm)

2000-5000

Rated Power(kW)

12-70Rated Torque(N·m)

38-200Rated Speed(rpm)

2000-4000

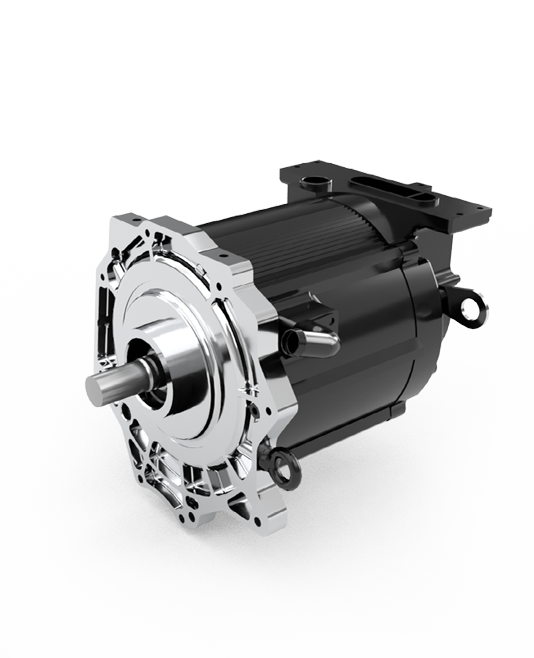

Rated Power(kW)

29-40Rated Torque(N·m)

120-150Rated Speed(rpm)

2000-3000

Rated Power(kW)

6-150Rated Torque(N·m)

26-800Rated Speed(rpm)

1500-3000

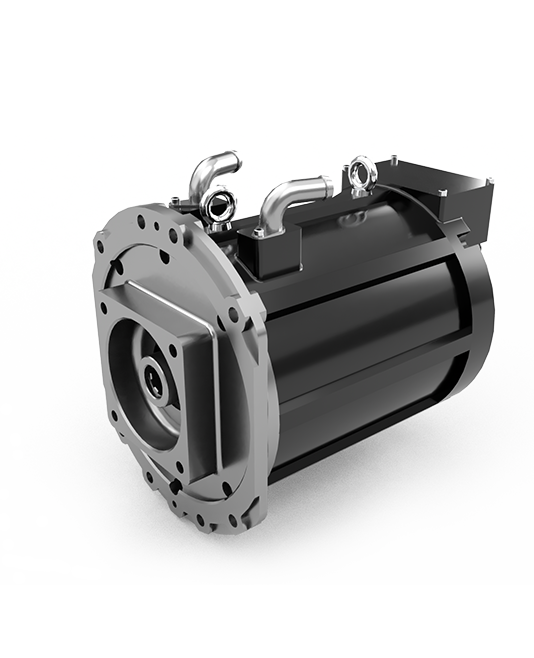

Rated Power(kW)

75-180Rated Torque(N·m)

190-300Rated Speed(rpm)

3700-5700

Rated Power(kW)

0.68-50Rated Torque(N·m)

1.8-200Rated Speed(rpm)

2000-4000Solution for your industry

Mature and powerful automation solutionsOur case

Turn your needs into innovation storiesCamera recognizes unordered grab loading

Project description: Project description: The project is a single station bevel loading and unloading project for customers. In this project, the robot completed a total of five steps of 3D camera recognition → grasping → secondary positioning → grasping → placing. This project solved the customer's on-site manpower and labor intensity problems, and increased the processing efficiency by more than 50%.Slewing bearing glue lifting equipment

Project information: The project is the automatic feeding of small micro-digging sleigh bearing in the customer's factory & Glue project. The project mainly uses a non-standardized intelligent workstation composed of slewing bearing loading station, angular positioning, gluing assembly and six-axis manipulator.Realize the need for robots to replace manual work and reduce labor intensity.Robot welding production line

Project information:The project is the customer's on-site arc welding pipeline welding project. The project mainly includes welding robot, welding mobile platform, welding clamping tool composition, using the welding robot's high stability, high consistency and continuous work characteristics instead of manual welding, while replacing manual welding will improve welding efficiency by 20%, welding quality by 20%.Track plate automatic loadingGluing

Production lineAutomatic

Project information: The project for the customer's on-site robot with glue coating machine to complete the glue coating work project. This project mainly uses the robot's high linear trajectory accuracy, high smooth transition of path inflection point, long arm span and high load characteristics to replace manual gluing work, effectively improving production efficiency and gluing quality.Loading and unloading of brake disc

We are AITRON

Everything about us